These frames are rubbish.

Over 400m frames are thrown away per year in North America alone.

On top of this every optical frame is supplied with plastic demo lenses which are then thrown away, contributing to an industry wide issue.

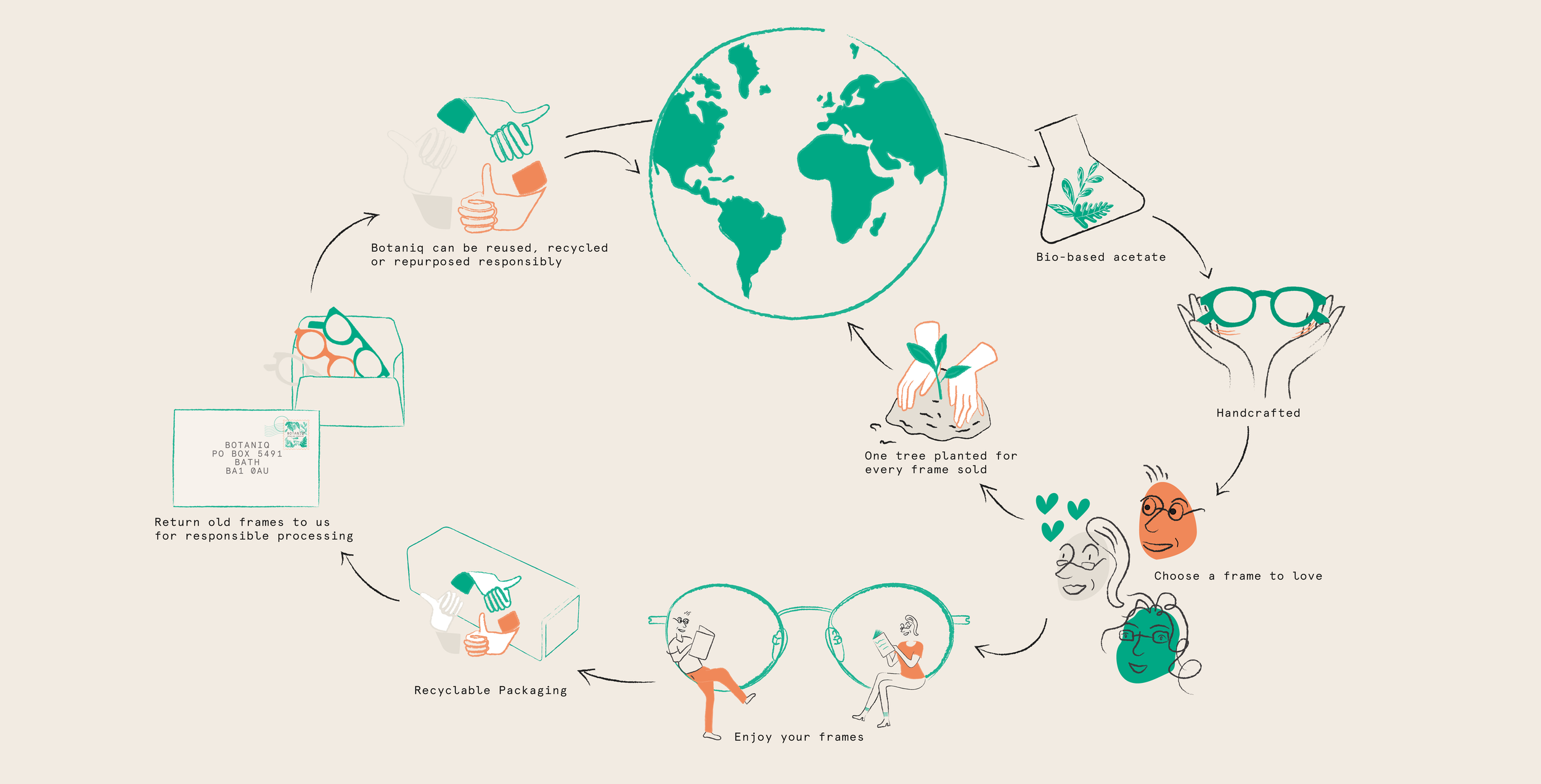

Producing the frames in a recyclable material was a small step, the real challenge was to complete the lifecycle of the frames and create a circular economy. In order to do this, and prove it!, every step of the process and element of the eyewear were interrogated to find a solution.

How could we be circular and not increase the retail price?

The largest challenge with using sustainable materials for the frames was that the majority of eyewear is produced in China, with very little produced elsewhere. Even frames that claim to be “Made in Italy” are typically manufactured in China with only the lenses being cut and mounted in Italy.

Distribution for Botaniq was intended for the UK and whilst local manufacture was explored, the investment in factories and sourcing of raw materials was cost prohibitive.

Manufacturing partners were selected in China only once they could provide total transparency on raw material and component sources, despite the higher COG.

Every component, from hinges to packaging, is recyclable or made from recycled materials, and old frames can be returned for responsible reuse.

In order to hit the target rrp with the increased COG, cost savings had to be found to avoid falling into the “Green Tax” trap.

Marketing is an easy target for budget cutting however it was a vital to raise awareness of the brand. One large cost which could be re-thought was how to approach the photoshoot.

A typical full-production campaign shoot costs around $100K, which could have offset the increased cost of goods. However, the brand still needed compelling imagery.

While AI image generation was still in its infancy in 2020, setting a creative direction that played to its strengths—combined with traditional post-production techniques—resulted in impactful visuals for the brand, covered the increased COG and created a circular economy.

Remarkably, most people still don’t realise the images are AI-generated!

Botaniq launched in 2021 and generated $1.76m in sales in 2022.

Interested to learn more about how our approach solved this?